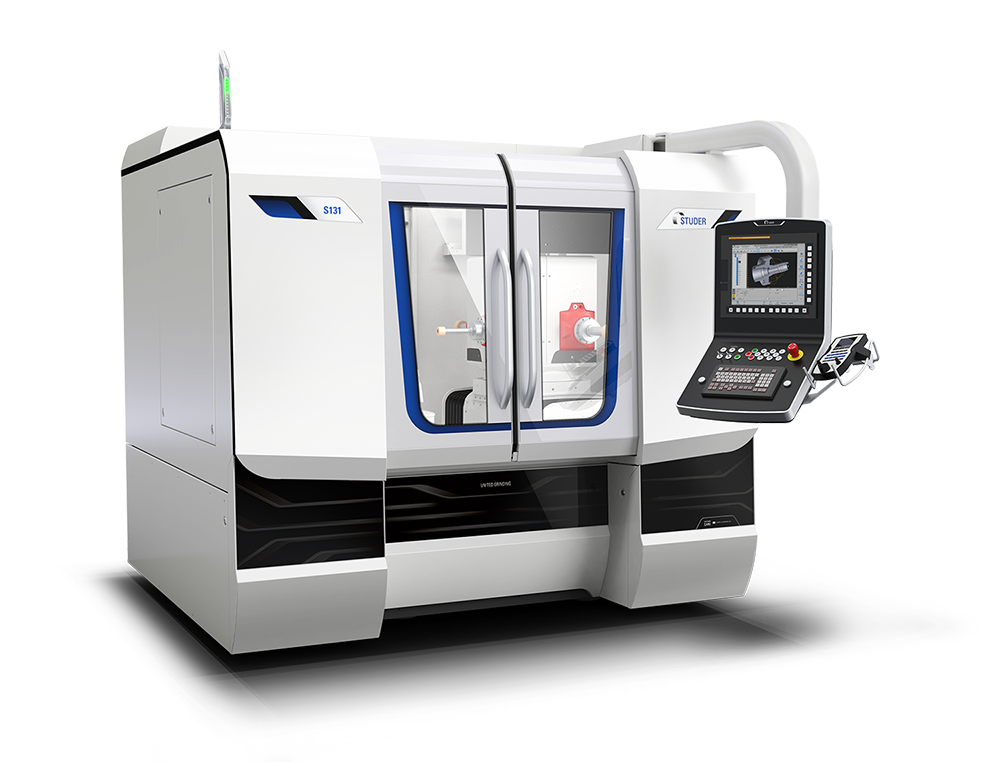

S131-The Universal Internal Grinding Machine

S131-The Universal Internal Grinding Machine

The S131 is a CNC universal internal cylindrical grinding machine of the latest generation. It has a host of sophisticated technical features such as the revolutionary StuderGuide® guide system, high-precision axis drives with linear motors, extremely fast direct drive of the grinding spindle turret, automatic swivelling of the workpiece table etc.

The workpiece length is 300 mm (11.8"), the maximum internal grinding length is 175 mm (6.9") and the external length is 125 mm (4.9"). The S131 is the ideal machine for grinding flange parts. Many workpieces are in the areas of machine tools, drive elements, aerospace and toolmaking.

Precision is the result of perfect interaction between a large number of different factors. The basis of the S131 is the machine bed comprising Granitan® S103 with its excellent dampening and favorable thermal behavior. The modules are ideally suited to each other and produced with the customary STUDER precision. The large distance between the guideways and the very rigidly constructed slides form the basis for the precision and productivity of this machine. All components involved in defining precision are temperature-stabilized.

StuderWIN/StuderSIM creates a stable programming environment and contributes to efficient use of the machine. A PC is integrated into the CNC control system. The possibility of fully integrating the in-process gauging and sensor technology for process monitoring as well as contact detection and automatic balancing systems in the control enable standardized programming of the different systems. The drive elements are optimally adapted to the control.

- Swing diameter above the table 250 mm (9.8")

- Max. workpiece length 300 mm (11.8")

- Internal grinding length 175 mm (6.9")

- Maximum workpiece weight 250 kg (550 lbs)

- StuderGuide® guide system with linear motors

- Grinding spindle turret with up to four grinding spindles

- Automatically swiveling workpiece table

- C-axis for the workhead for form and thread grinding

- Full enclosure with two sliding doors

- Granitan® S103 mineral casting machine base

- Very simple operation and programming thanks to StuderWIN or StuderSIM

- Short setup and resetting times e.g. with STUDER Quick-Set

- Standardized interfaces for loader and peripheral devices

- Up to three HF grinding spindles in a linear arrangement

- Large selection of internal and external spindles

- C axis for the workhead for form and thread grinding

- Manual A axis for precise thread grinding

- Various dressing options

- Full enclosure with sliding door

- Integrated or autonomous loading systems

- Measuring probe

- SimCT offline simulation software

- Large range of accessories

- Standardized interface for loader and peripheral devices